MEMORY SHAPES

Bloodshed

Milkface

Listening for your secrets

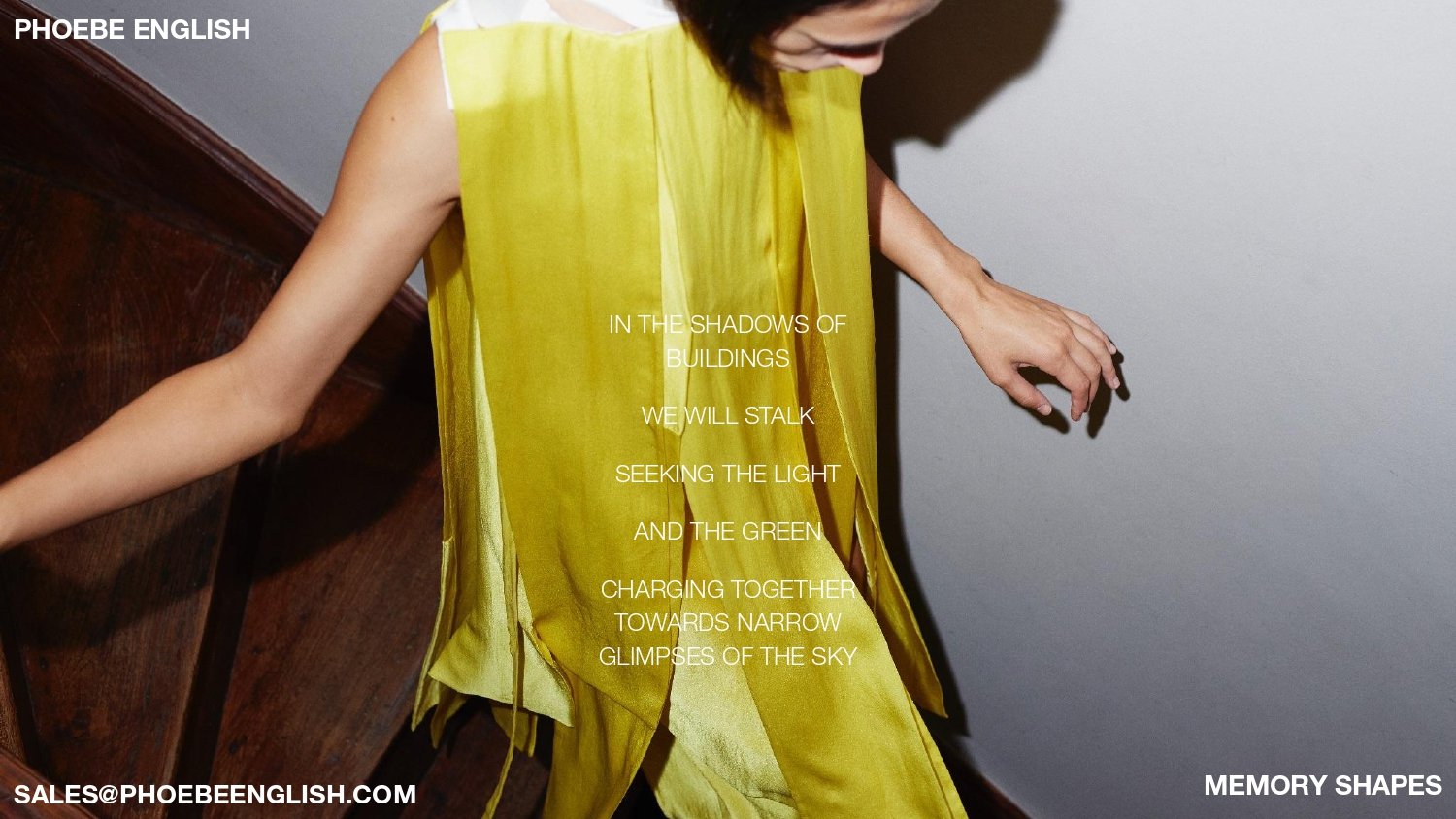

In the shadows of buildings

We will stalk

Seeking the light

And the green

Charging together towards narrow glimpses of the sky

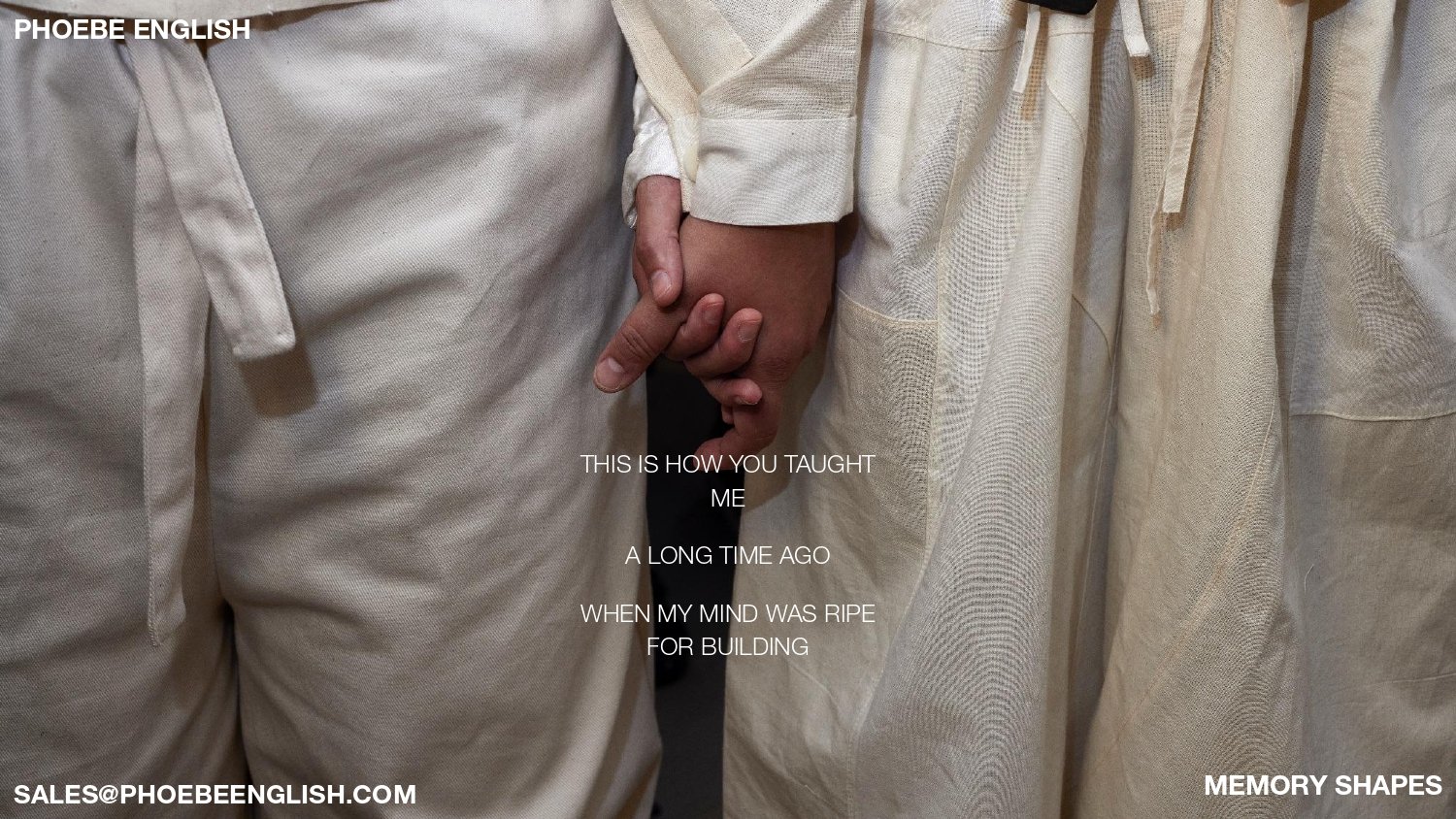

This is how you taught me

A long time ago

When my mind was ripe for building

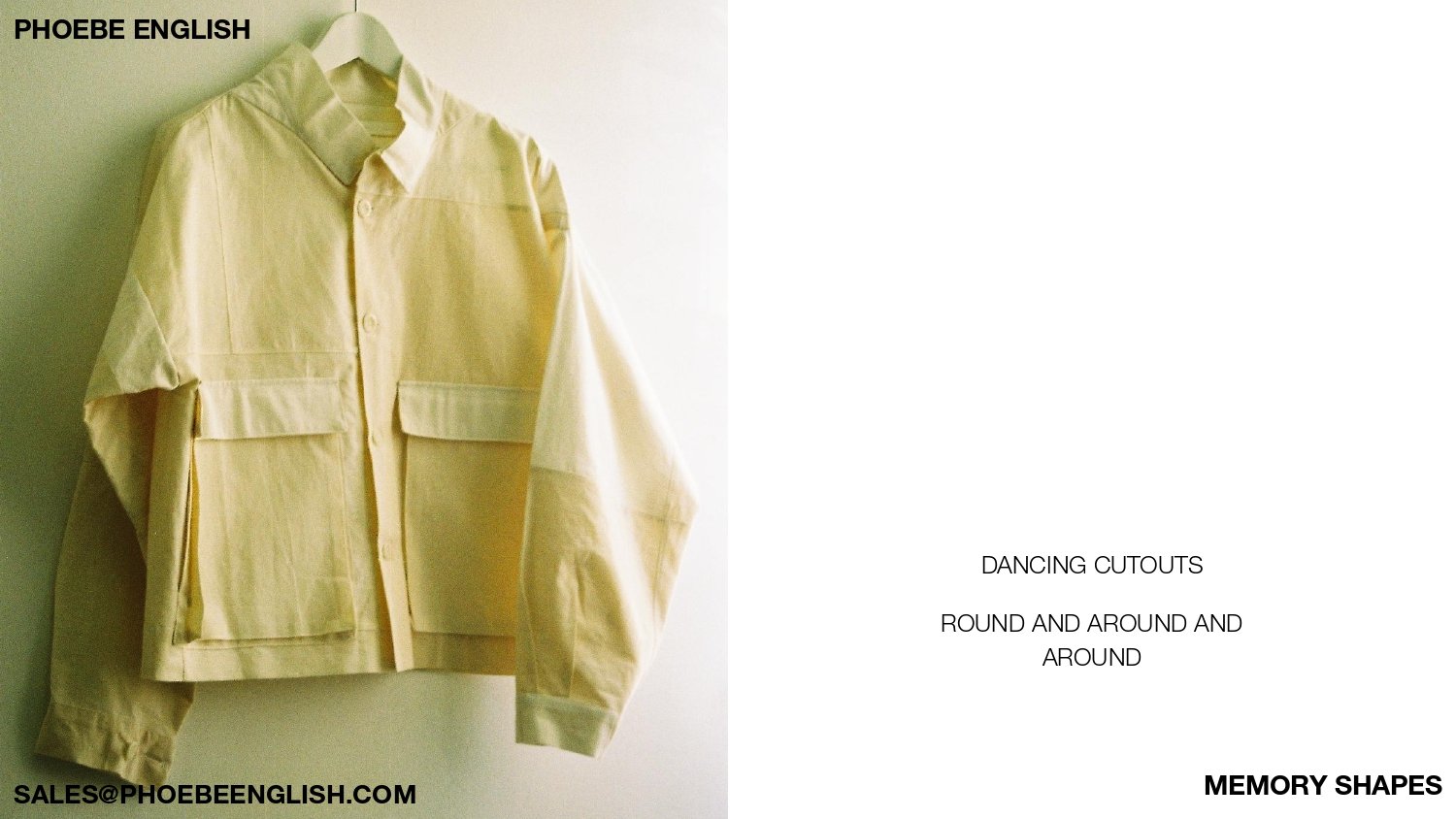

Dancing cutouts

round and around and around

material

going unused and foraged: hotel bedding, bridal waste off cuts, surplus, faulty, using up all that we have left

virgin: traceable British wool wadding, milk casein buttons, corozo nut buttons

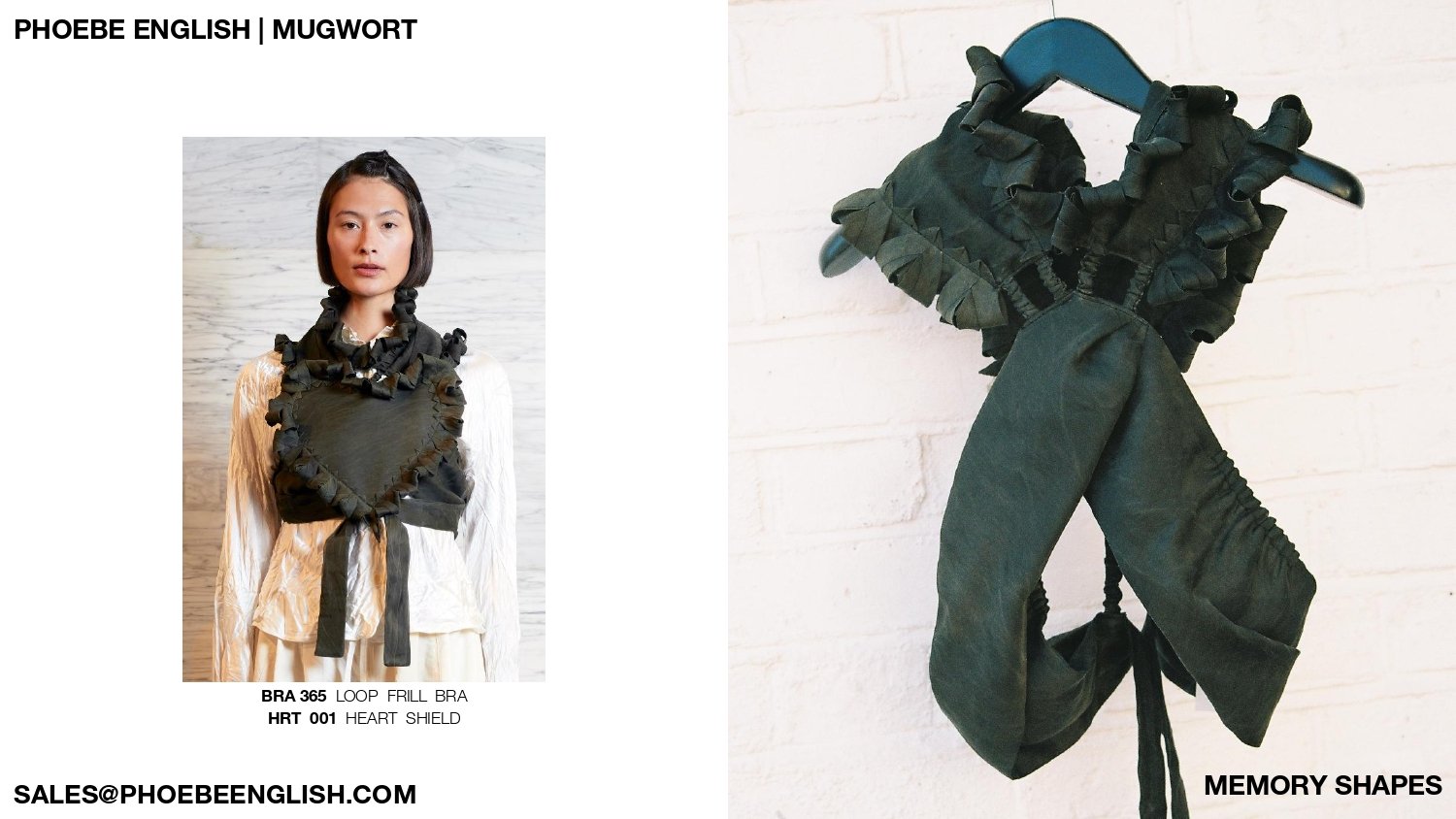

botanical colour

yellow from Weld (Suffolk), red from Madder (Guernsey), green from Mugwort (Warwickshire), inky from tropical Logwood and hand collected oak galls.

surface

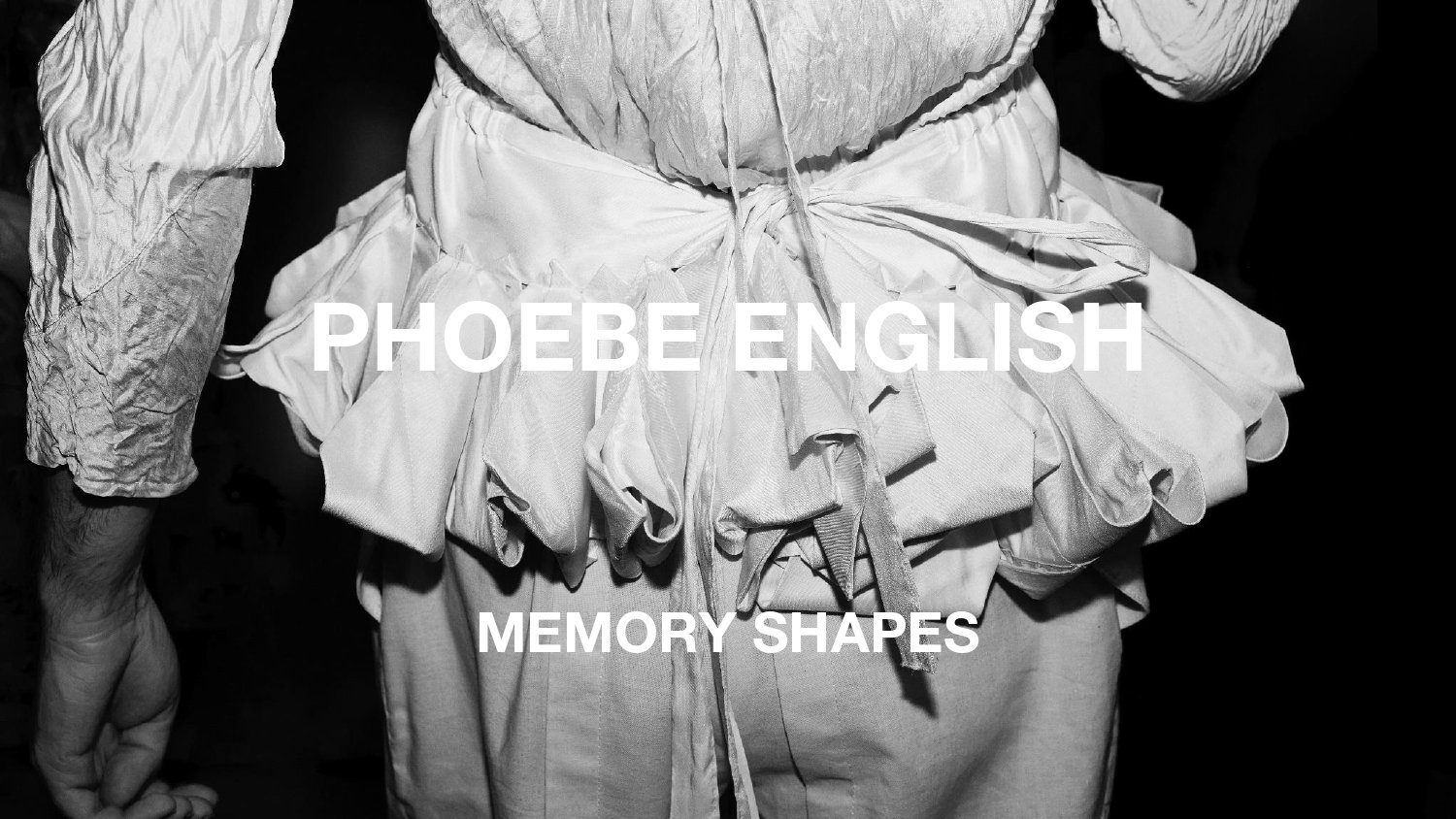

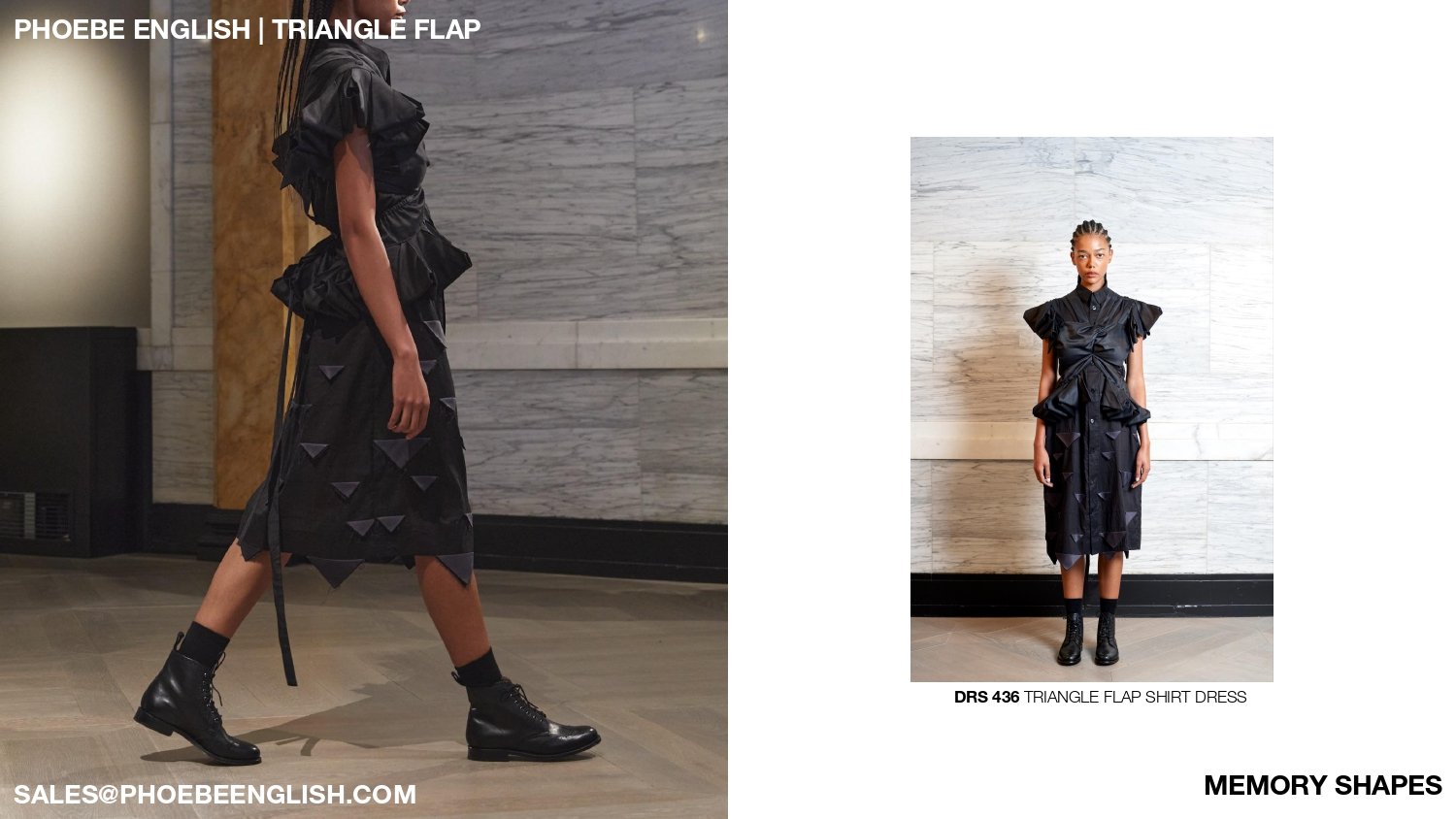

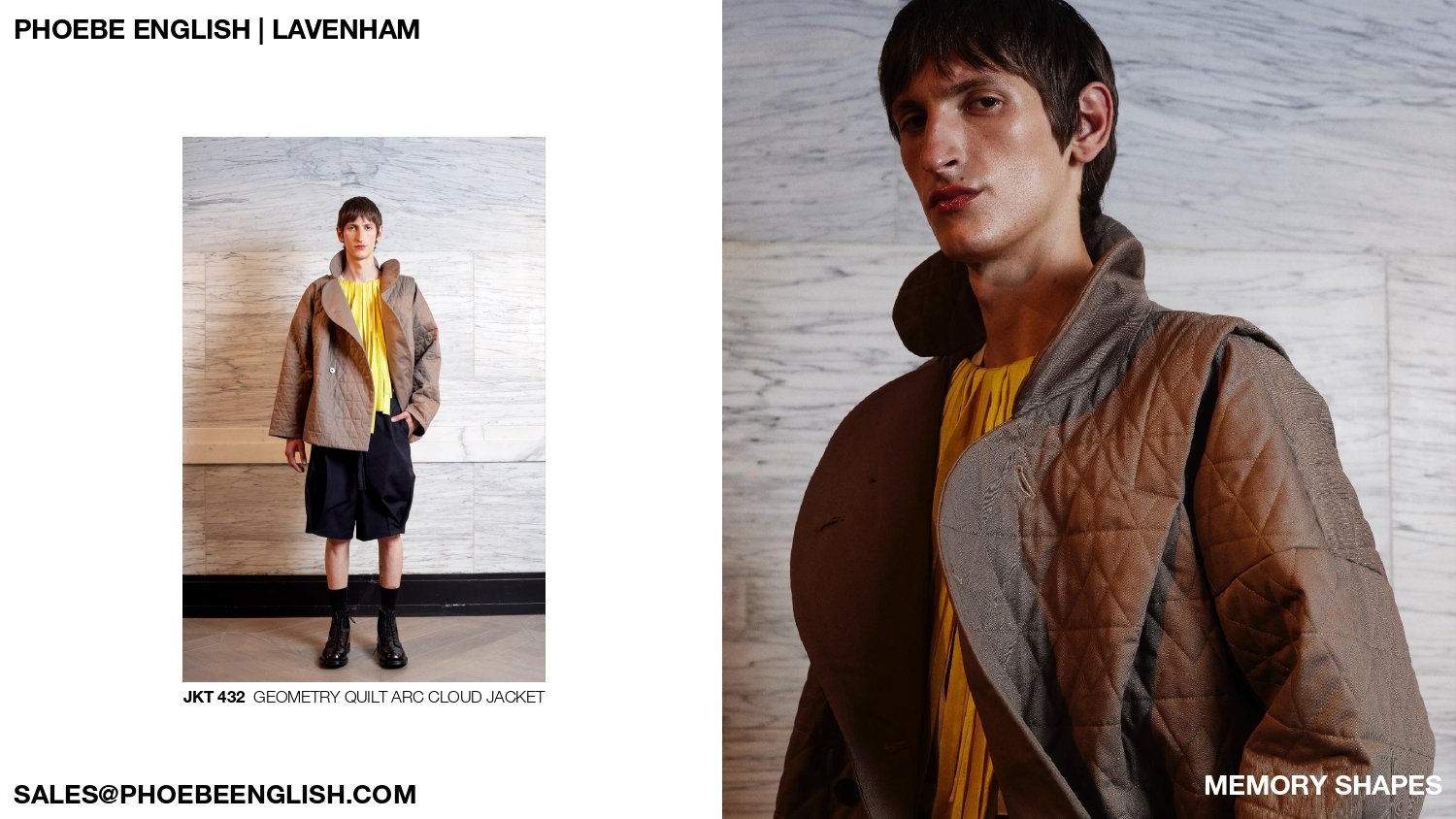

fold on fold on fold, arbitrary triangle, crinkle, neatly looping frill, freely falling lengths, geometric quilting

forms

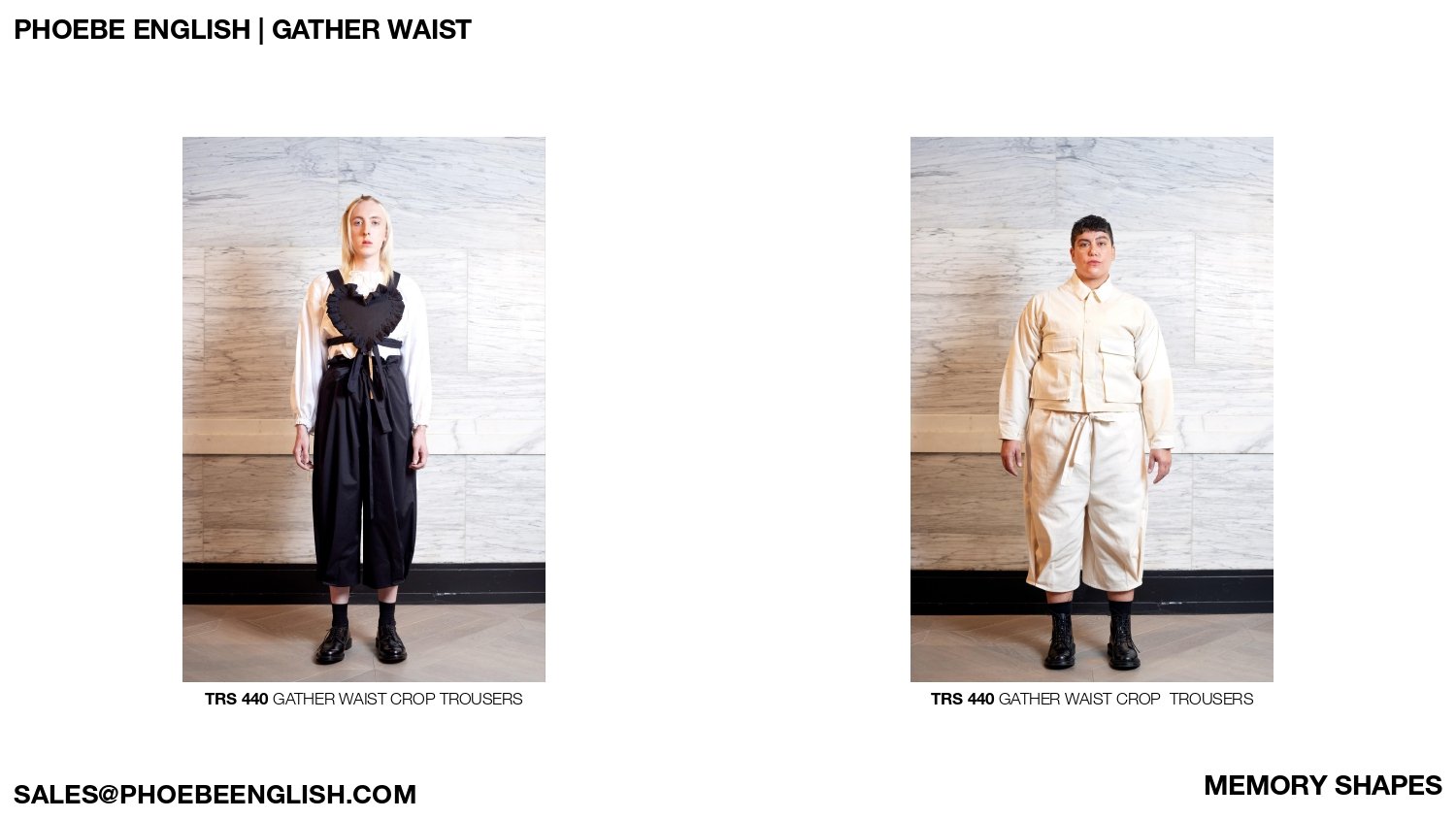

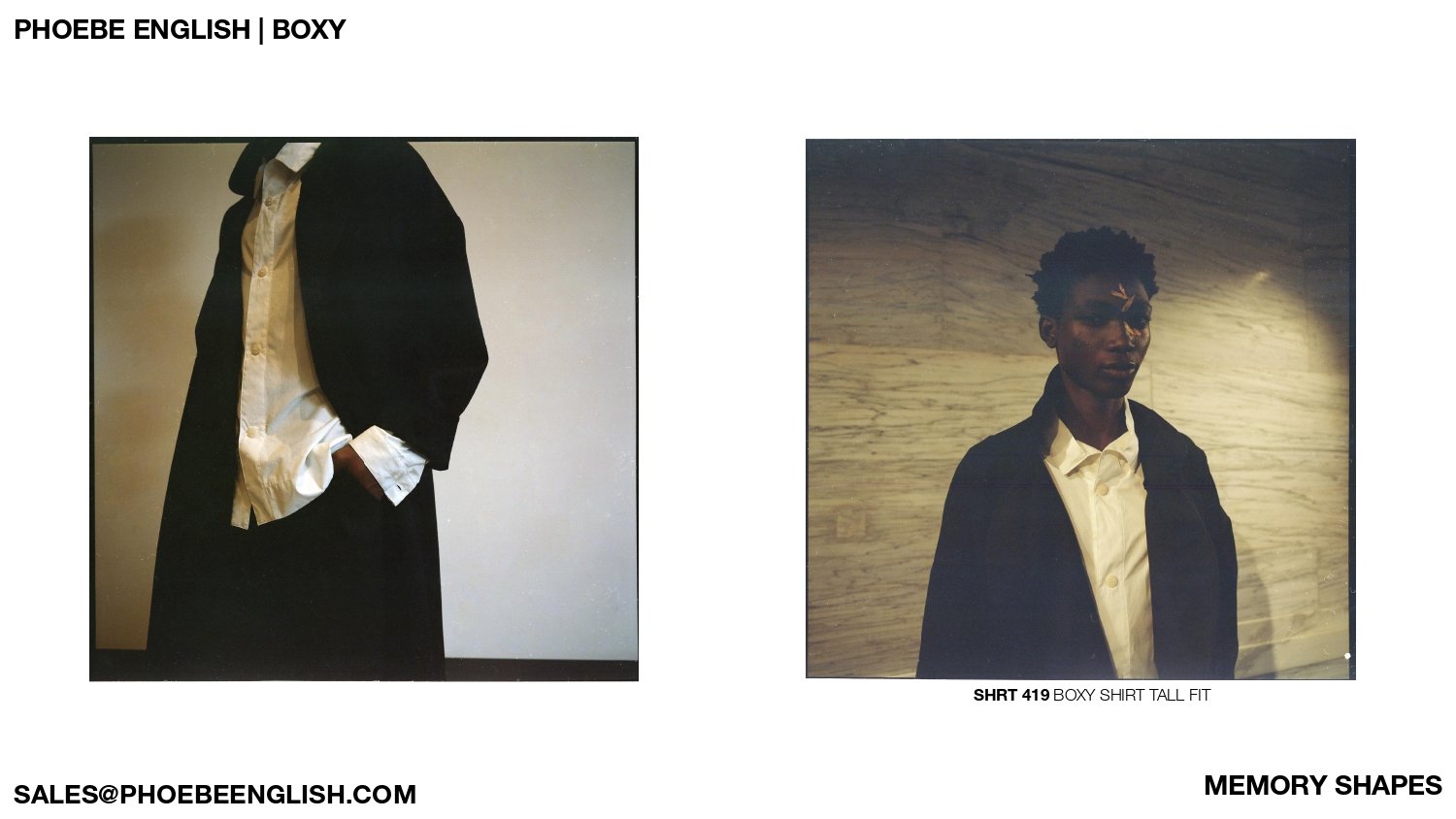

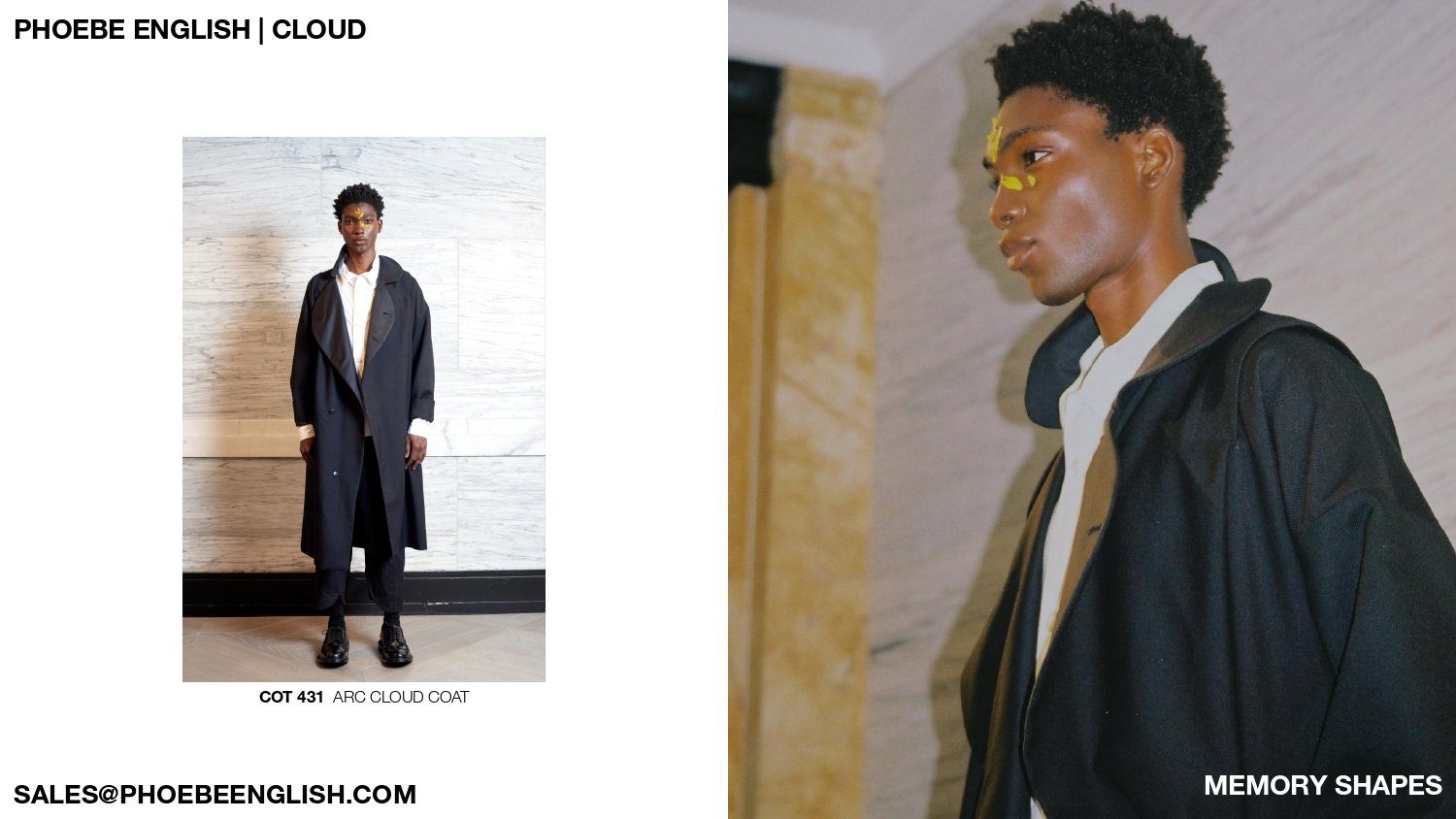

criss crossing, curving cloud, love heart, shield, loose gathers, tight gathers, pinched collar, sharp overlaid edges

Collaborations | Partnerships

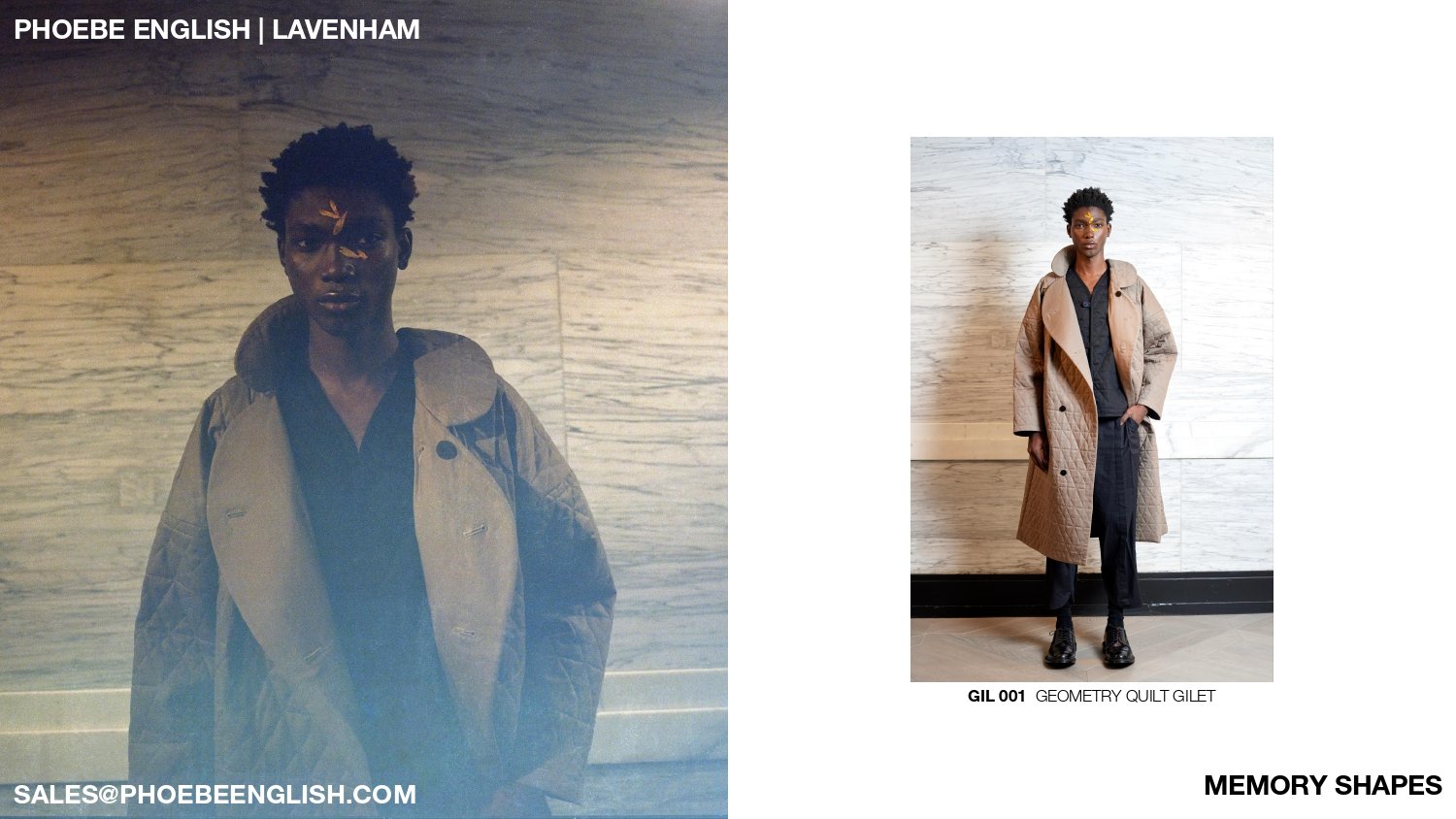

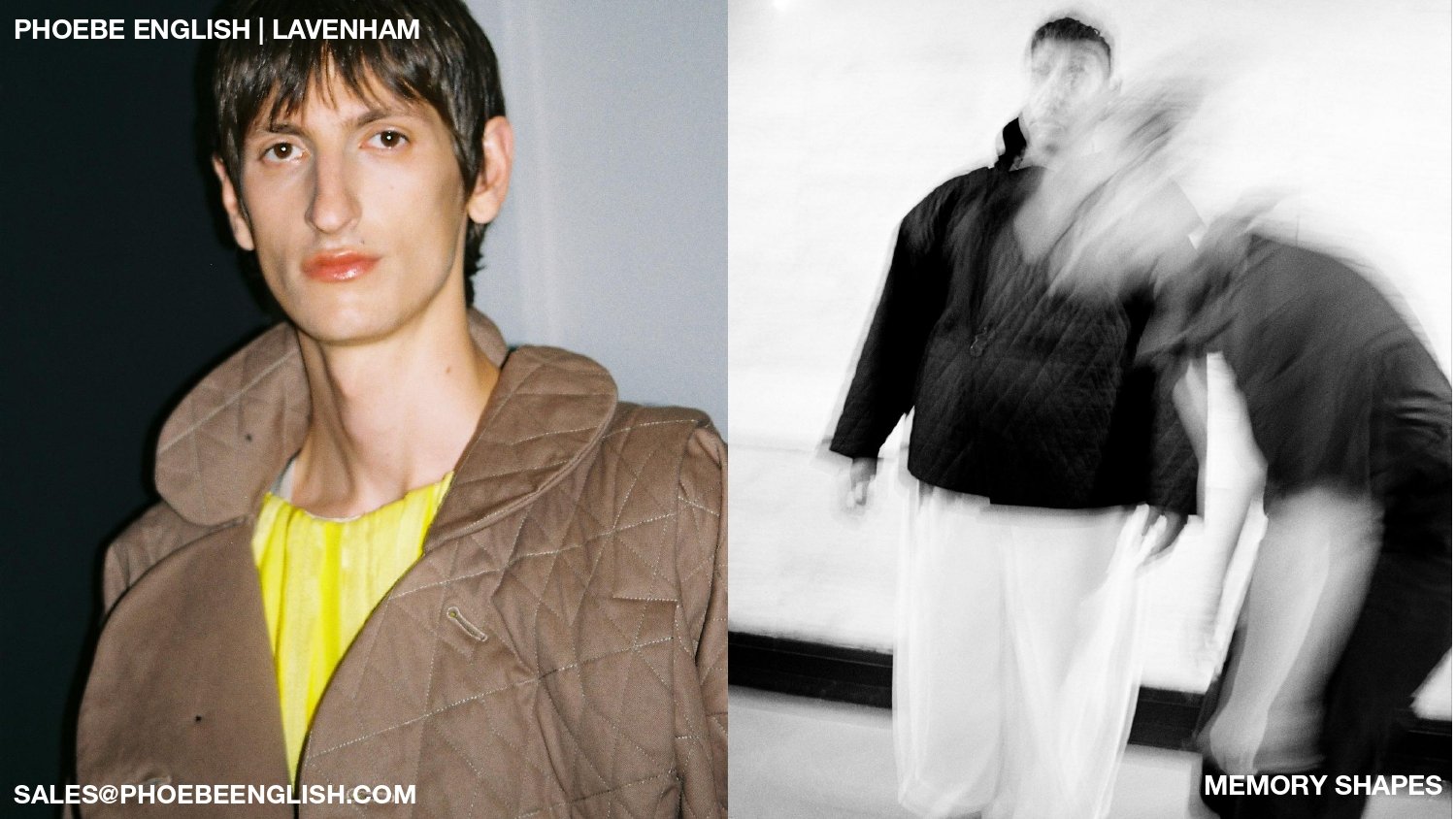

Phoebe English and Lavenham

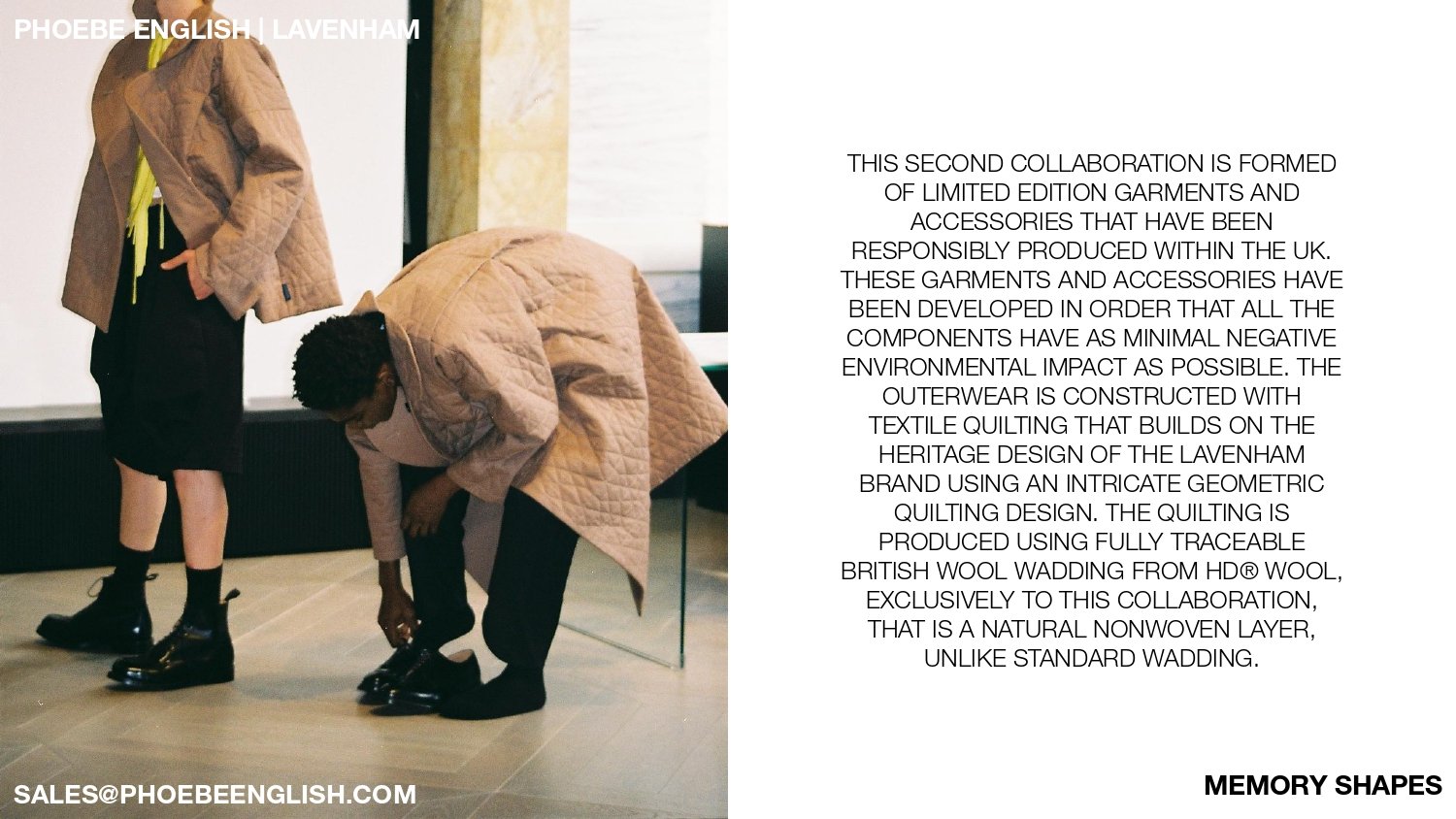

This collection includes our second edition of the Phoebe English and Lavenham collaboration. Heritage British outerwear brand Lavenham is known for its expertise in quilted outerwear and works with predominantly British cloth manufacturers, renowned for their high quality and hardworking fabrics. Every fit-for-purpose piece is made on site in the Lavenham factory, based in Suffolk.

This second collaboration is formed of limited edition garments and accessories that have been responsibly produced within the UK. These garments and accessories have been developed in order that all the components have as minimal negative environmental impact as possible. The outerwear is constructed with textile quilting that builds on the heritage design of the Lavenham brand using an intricate geometric quilting design. The quilting is produced using fully traceable British wool wadding from HD® Wool, exclusively to this collaboration, that is a natural nonwoven layer, unlike standard wadding.

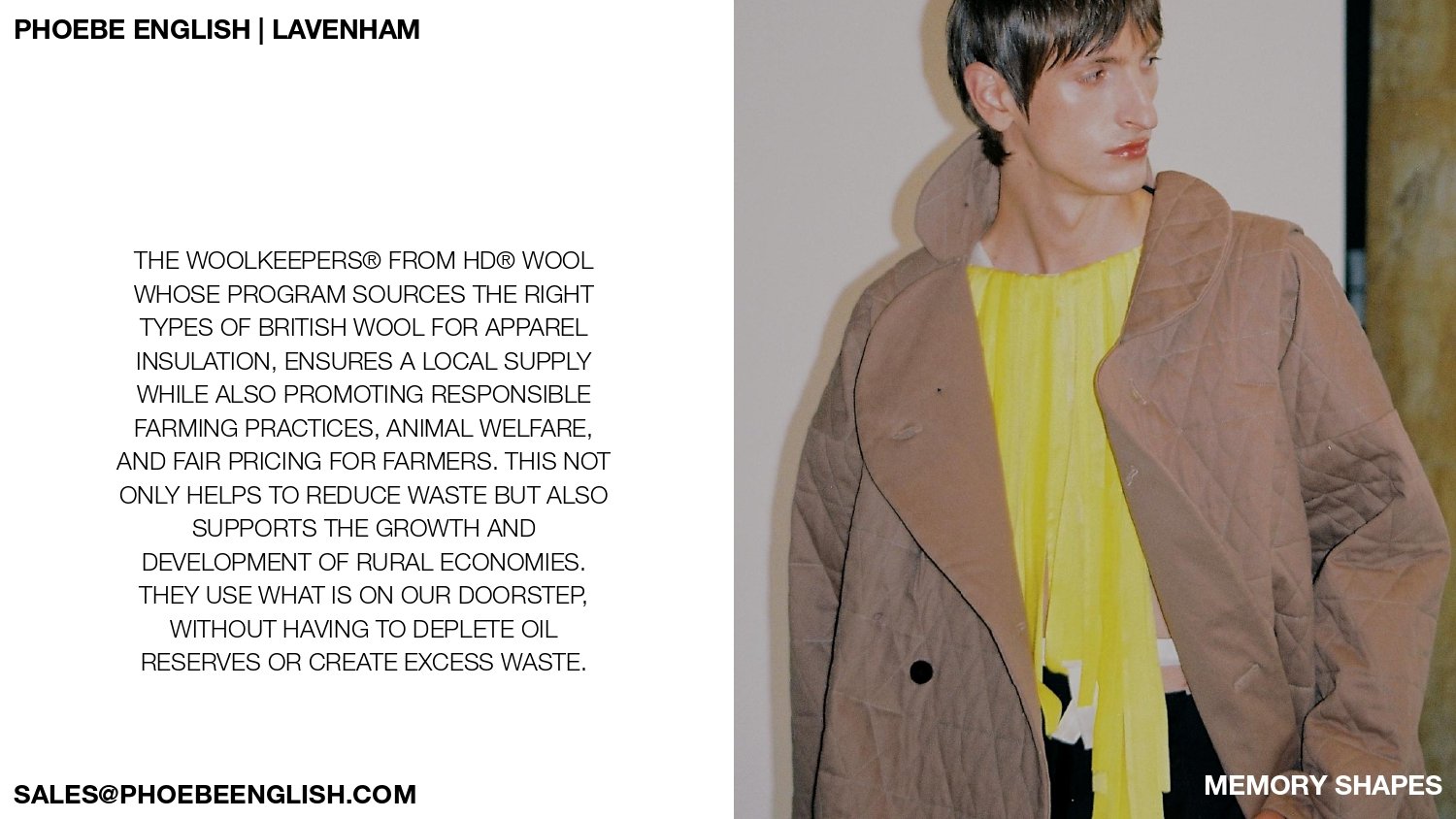

The Woolkeepers® from HD® Wool whose program sources the right types of British wool for apparel insulation, ensures a local supply while also promoting responsible farming practices, animal welfare, and fair pricing for farmers. This not only helps to reduce waste but also supports the growth and development of rural economies. They use what is on our doorstep, without having to deplete oil reserves or create excess waste.

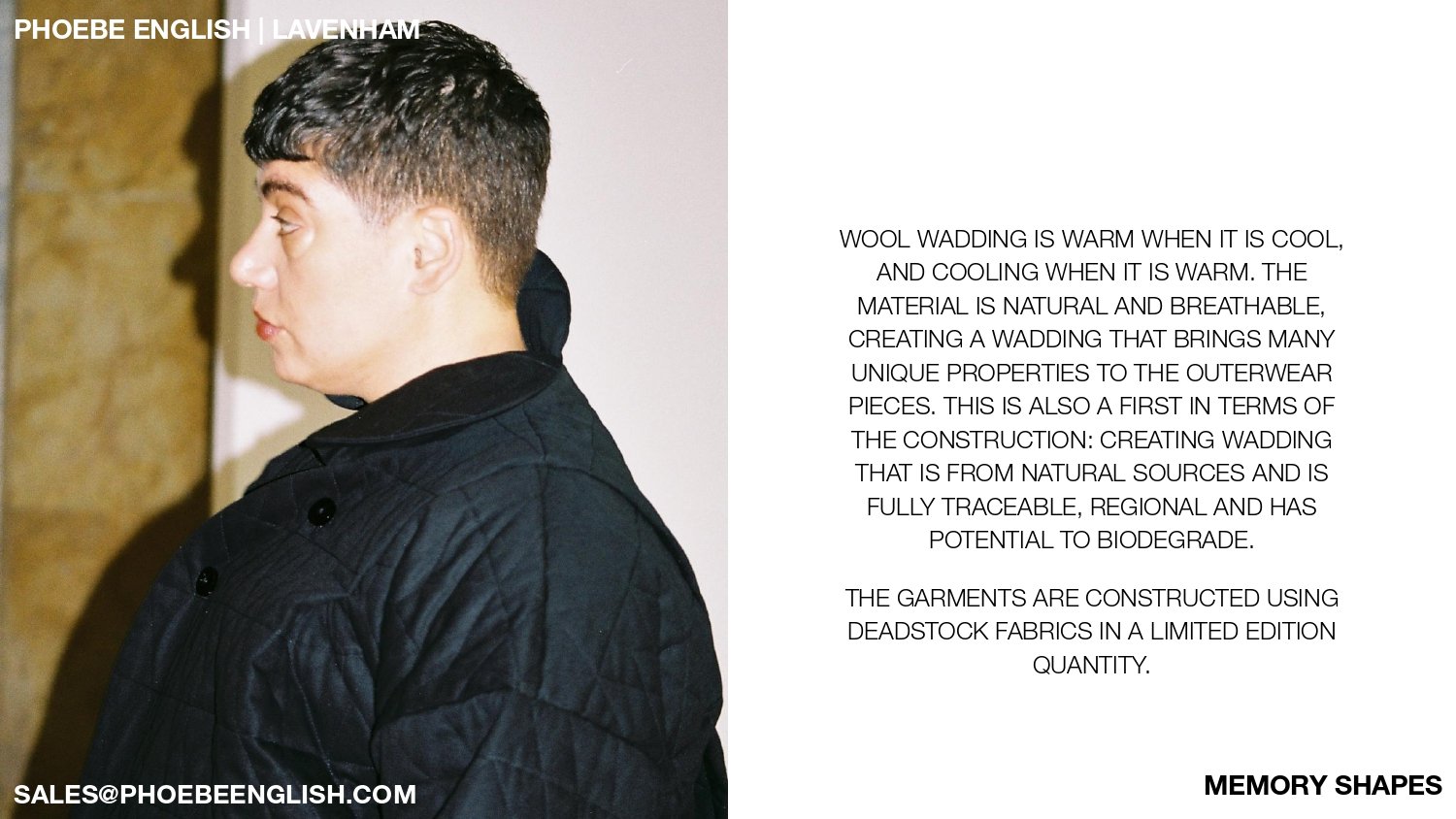

Wool wadding is warm when it is cool, and cooling when it is warm. The material is natural and breathable, creating a wadding that brings many unique properties to the outerwear pieces. This is also a first in terms of the construction: creating wadding that is from natural sources and is fully traceable, regional and has potential to biodegrade.

The garments are constructed using deadstock fabrics in a limited edition quantity.

Glass Onion with the support of the BFTT

With the support of the Business of Fashion, Textiles & Technology Partnership (BFTT) SME R&D Follow on Funding, we have been able to partner with a new producer: Glass Onion Vintage.

Glass Onion is a leading vintage clothing company, processing up to 20,000 kgs of second hand clothing each week, all previously heading for landfill. Based in Barnsley, South Yorkshire, Glass Onion has been regenerating its local area with employment opportunities and is accredited by The Living Wage Foundation. Their HQ is home to their in-house factory and skilled sewing and technical team who, combined, have over 500 years of experience in the sewing industry. We have worked with them to produce some of the pieces in this collection, such as carefully constructed patchwork panels of new fabric made from our accumulated silk off-cuts as well as remaking our toiles into new fabric panels to put into new garments. We have worked closely with them to produce the garments themselves.

The richly textured crinkle family, utilises fabric waste streams and our alternative sourcing networks. Made from beautiful bridal silk offcuts, these deluxe silks create new garments rather than reaching landfill. It takes almost a year to save up enough small pieces of silk to make a series of our crinkle garments.